Products

Products

Specification and model: AT32-AT400

Body material: die cast aluminum

Control mode: double acting, single acting

Air Supply: 0.3-0.8Mpa

Product Overview:

Pneumatic actuator is an actuating device that uses pneumatic pressure to drive the opening, closing or regulating of valves, also known as pneumatic actuator or pneumatic device, but generally referred to as pneumatic head. Pneumatic actuators are sometimes equipped with certain auxiliary devices. Commonly used are valve positioners, limit switches, solenoid valves, and manual control mechanisms.

Model: 20NM-2000NM (output Torque)

Body material: die cast aluminum

Control mode: Rotary Model, Liner Model, Multi turn

Voltage: 12VDC, 24VDC, 24VAC, 110VAC, 220VAC, 380VAC, 415VAC

Product Overview:

Electric actuators generally refer to electric actuators. The most extensive definition of an actuator is a driving device that can provide linear or rotational motion, utilizing a certain driving energy source and working under the action of a certain control signal. The actuator uses liquid, gas, electricity, or other energy sources and converts them into driving force through motors, cylinders, or other devices.

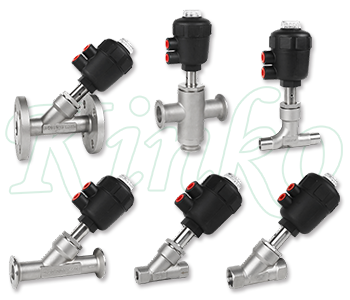

Nominal diameter: DN10-DN100

Body material: SS304, SS304L, SS316, SS316L

Connection : Thread, Welding, Tri-clamp, Flange

Control methods: ON-OFF type, adjustable type, manual control, pneumatic control, electric control

Product Overview:

Angle seat valve is a directional angle seat valve operated by a single acting pneumatic actuator with spring safety protection. Angle seat valves are widely used for short-term frequent start-up, maintaining flow rate can save space, and have the characteristics of sensitive response and accurate action. When used in conjunction with solenoid valves, pneumatic control can accurately control gas and liquid flow rates. It can meet the requirements of accurate temperature control and liquid dripping.

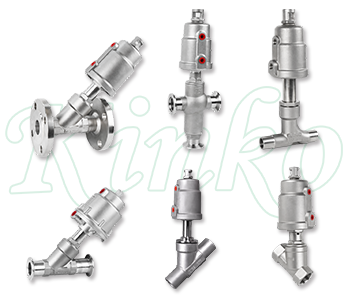

Nominal diameter: DN10-DN100

Body material: SS304, SS304L, SS316, SS316L

Connection : Thread, Welding, Tri-clamp, Flange

Control methods: ON-OFF type, adjustable type, manual control, pneumatic control, electric control

Product Overview:

Angle seat valve is a directional angle seat valve operated by a single acting pneumatic actuator with spring safety protection. Angle seat valves are widely used for short-term frequent start-up, maintaining flow rate can save space, and have the characteristics of sensitive response and accurate action. When used in conjunction with solenoid valves, pneumatic control can accurately control gas and liquid flow rates. It can meet the requirements of accurate temperature control and liquid dripping.

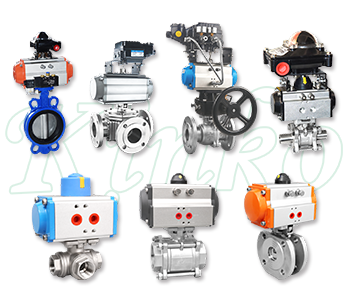

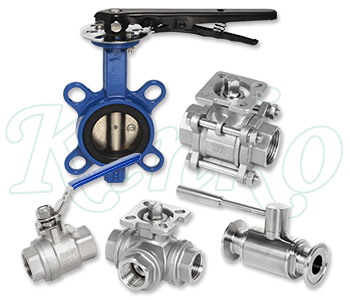

Nominal Diameter

Ball valve: DN15-DN200

Butterfly valve: DN50-DN600

Body material: stainless steel, carbon steel, cast steel, cast iron, UPVC,PVDF

Control mode: ON-OFF type, adjustable type, straight through, three-way, multi-channel

Product Overview:

Pneumatic valve is a valve that uses compressed air to drive the movement of multiple sets of combined pneumatic pistons inside the actuator. The product is widely used in the transportation pipelines of various petroleum and chemical raw materials and products, such as flow control and cutoff of crude oil, refined oil, chemical liquids, etc.

Nominal Diameter

Ball valve: DN15-DN200

Butterfly valve: DN50-DN600

Body material: stainless steel, carbon steel, cast steel, cast iron, UPVC,PVDF

Control mode: ON-OFF type, adjustable type, straight through, three-way, multi-channel

Product Overview:

Electric valve is a device that controls valve opening and closing through an electric actuator. It can not only achieve the function of opening and closing, but also adjust the valve position of the regulating electric valve. The product is widely used in the transportation pipelines of various petroleum and chemical raw materials and products, such as flow control and cutoff of crude oil, refined oil, chemical liquids, etc.

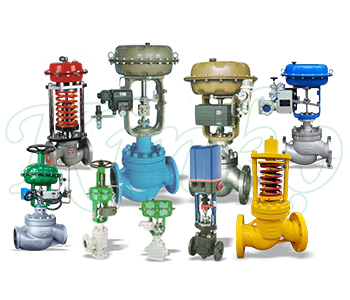

Nominal diameter: DN20-DN200

Body material: stainless steel, cast steel, cast iron, forged steel

Control methods: ON-OFF type, regulating type, pneumatic control, electric control, direct, three-way, multi-channel

Product Overview:

Regulating valves generally refer to control valves, which are composed of two main components: valve body assembly and actuator assembly (or actuator system). They are divided into four series: single seat series control valves, double seat series control valves, sleeve series control valves, and self operated series control valves. The variations of the four types of valves can lead to many different applicable structures, each with its own unique applications, characteristics, advantages, and disadvantages. Regulating valves can be widely used for precise control of various situations such as different temperatures, pressures, and flow rates.

Positioner:

YT-1000R,YT-1000L,YT-1200R,YT-1200L

Limit switch:

APL-210,APL-310,APL-410,APL-510,DS500

Hand operated mechanism

Solenoid valve: 24VDC, 220VAC, 110VAC

Installation bracket connector: can adapt to various valves such as ball valves, butterfly valves, etc

Nominal Diameter

Gate valve: DN15-DN600

Globe valve: DN15-DN600

Check valve: DN15-DN600

Ball valve: DN15-DN600

Butterfly valve: DN50-DN1600

Body material: stainless steel, cast steel, carbon steel, forged steel

Manufacturing standards: GB; ANSI; JIS

Product Overview:

Industrial valves are control components in pipeline fluid transportation systems. They are used to change the cross-section of the passage and the direction of medium flow, and have functions such as diversion, cutoff, regulation, throttling, check, diversion, or overflow pressure relief. Valves used for fluid control, with nominal diameters ranging from extremely small instrument valves to industrial pipeline valves with diameters up to 10m.

Nominal diameter: DN10-DN200

Body material: SS304, SS304L, SS316, SS316L

Connection methods: Thread, Welding, Tri-clamp, Flange

Control methods:ON-OFF type, regulating type, manual control, pneumatic control, electric control

Product Overview:

Designed specifically for the food, pharmaceutical and other industries, it strictly controls cleanliness standards and seamlessly meets the demands of hygienic production. It meets the high hygiene requirements of industries such as food and medicine. It is fully sealed to prevent pollution, easy to clean and corrosion-resistant.